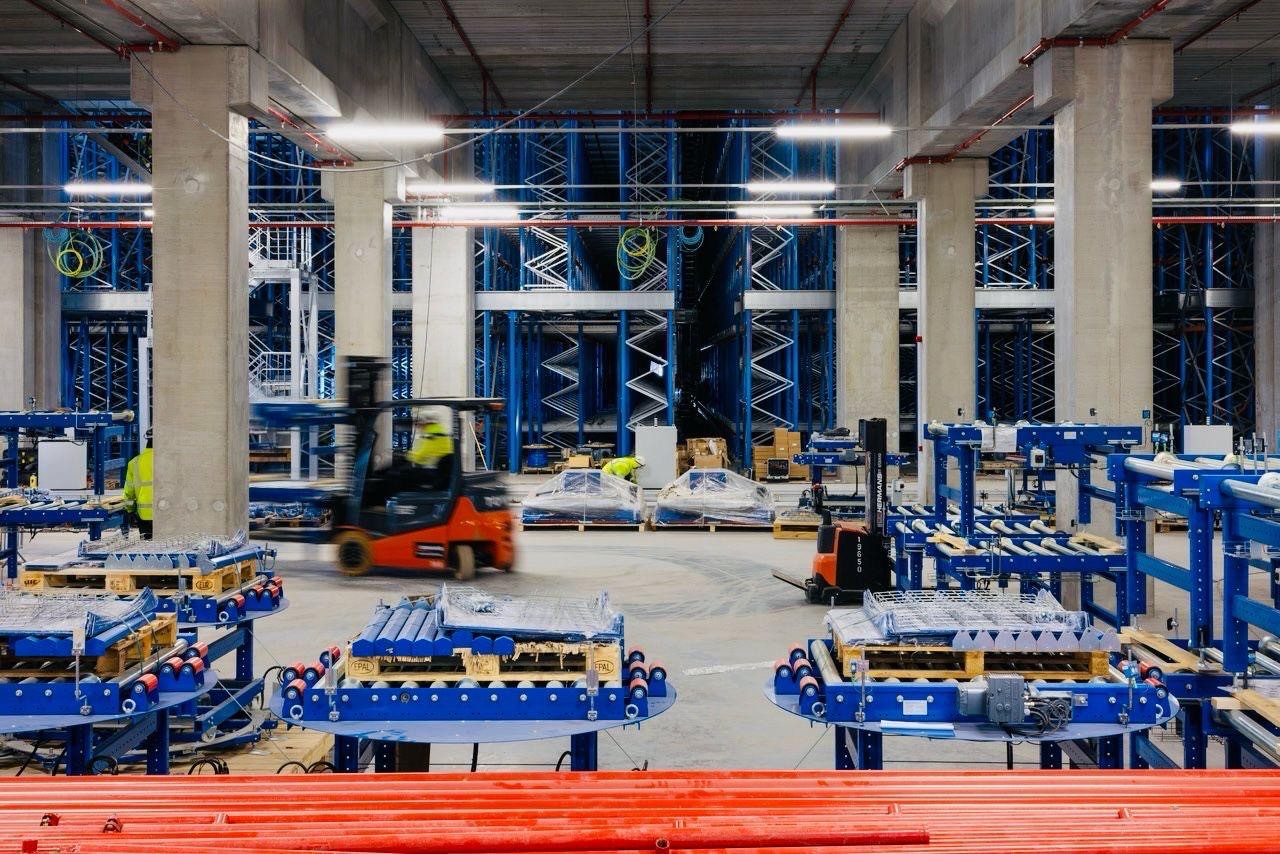

The automated and conventional warehouses are seamlessly connected, offering maximum flexibility for our customers to store a wide range of valuable goods.

The total warehouse provides storage for 47.500 Euro pallets.

The Following Ratios have been used in regards of the pallet heights and weights for the different storage locations:

- Suppliers stock of max 2.7 m

- Maximum weight of 1.200 kg/UK pallet or 1.000 kg/EURO pallet

- Storage of double stacked pallets, combined maximum of 1000 kg

Above the expedition zone, a mezzanine has been built for additional automated pallet storage and to supports value-added services (VAS), such as repackaging or labeling, after which pallets can be automatically returned to storage.